Welcome to Epoxy Evolution!

Your Trusted Partner in Epoxy and Concrete Flooring Solutions in Barrow County, GA!

Welcome to Epoxy Evolution!

Your Trusted Partner in Epoxy and Concrete Flooring Solutions in Barrow County, GA!

About Us

THE BEST FLOORING SOLUTIONS FOR YOUR GARAGE, BASEMENT, DRIVEWAY, OR PATIO!

At Epoxy Evolution, we specialize in providing top-tier epoxy flooring and concrete coating solutions tailored to meet your specific needs. Our team of experts based in Winder, GA, is committed to delivering affordable and durable flooring systems that stand the test of time. Whether you're looking for a sleek finish for your home garage or a robust flooring solution for high-traffic commercial areas, we have the expertise to bring your vision to life.

Why Choose Epoxy Evolution LLC?

1. Expertise in Epoxy and Polyaspartic Coatings

At Epoxy Evolution LLC, we specialize in high-quality epoxy and polyaspartic coatings. Our expertise lies in offering solutions that are not only durable but also aesthetically pleasing, ensuring your space looks and feels exactly how you envision it.

2. Tailored Solutions for Every Space

Whether it's a garage, industrial area, or a commercial space, we offer custom coatings to fit your specific needs. Our team works closely with you to understand your requirements and delivers solutions that are both practical and visually appealing.

3. Unmatched Quality and Durability

Our coatings are designed to withstand the rigors of daily use. They are resistant to wear and tear, making them a long-lasting investment for any property. Our focus is on providing a product that stands the test of time.

4. Eco-Friendly and Safe Coatings

Our coatings are designed to withstand the rigors of daily use. They are resistant to wear and tear, making them a long-lasting investment for any property. Our focus is on providing a product that stands the test of time.

Our Services

Types Of Flooring For Residential & Commercial Properties

Metallic

Polished Concrete

Countertops

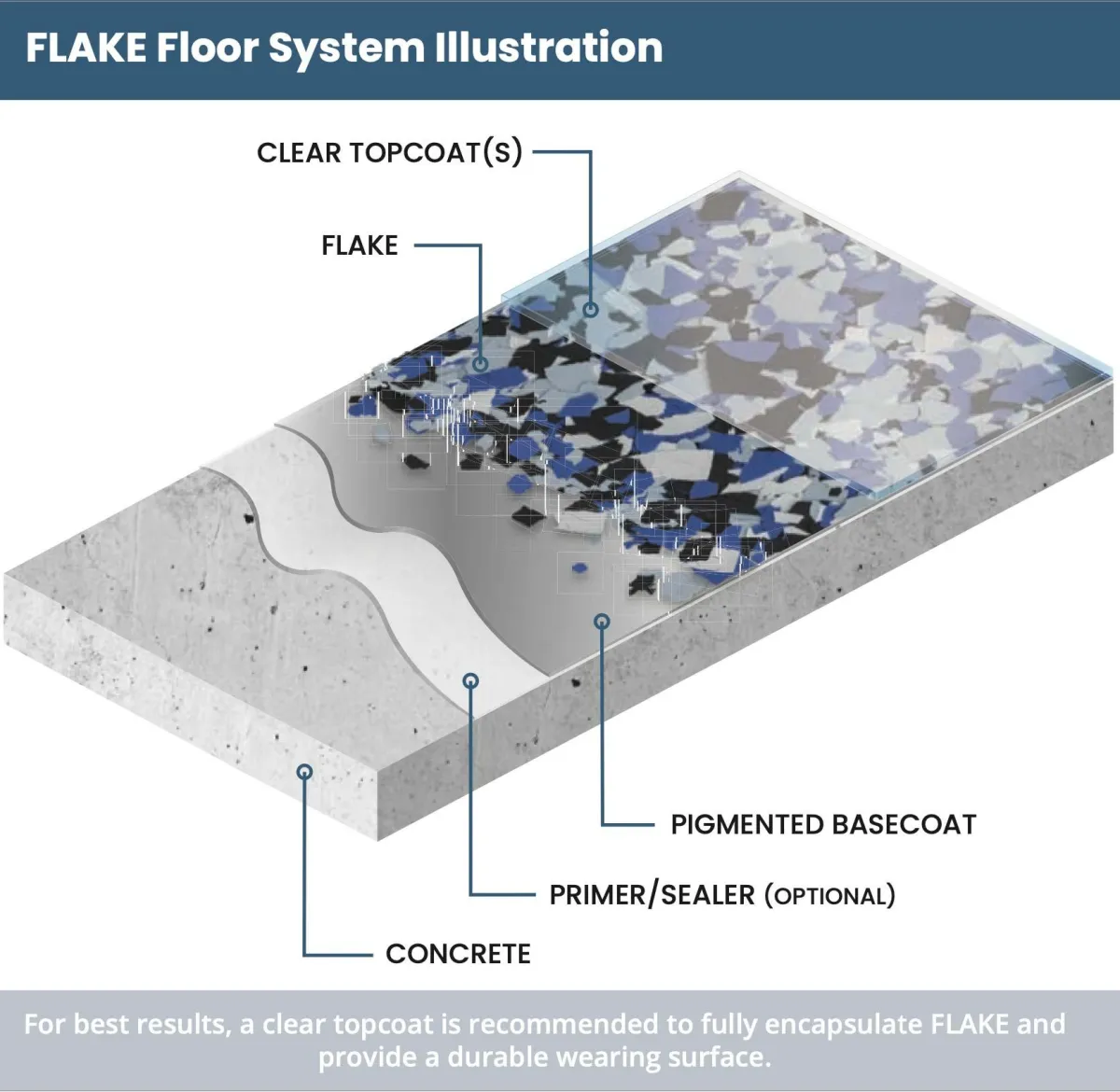

Flake

Glitter

3D/Logos

Quartz

Solid Color

Our Processes

1. Personalized Consultation

We start with understanding your vision and requirements.

2. Expert Installation:

Our team of skilled professionals ensures a flawless application, providing a smooth and even finish.

3. Rapid Completion:

We value your time. Our efficient process ensures that your space is ready for use in the shortest possible time.

1. Personalized Consultation

We start with understanding your vision and requirements.

2. Expert Installation:

Our team of skilled professionals ensures a flawless application, providing a smooth and even finish.

3. Rapid Completion:

We value your time. Our efficient process ensures that your space is ready for use in the shortest possible time.

Our Floor Laying Process

Testimonials

Our Client Reviews

We take pride in the positive feedback we receive, as it reinforces our commitment to providing top-quality flooring solutions and exceptional service. Your kind words inspire us to keep exceeding your expectations.

Epoxy Evolution LLC

ABOUT THE FOUNDER

Meet Andre Harris, a distinguished Iraqi war veteran hailing from Pittsburgh, PA, stands as the dynamic Founder, CEO, and creative force behind Epoxy Evolution. His artistic odyssey took flight in 2017, sparked by a desire to craft 'something different' for his personal space, which unveiled his extraordinary, latent talent.

In his personal life, Mr. Harris cherishes his role as a devoted husband to his high school sweetheart and as a loving father to their three wonderful children. His mission extends beyond artistic creation; he is deeply committed to providing an exemplary life for his family and inspiring others to pursue their passions with conviction.

FAQS

1. What are the benefits of Polyaspartic or epoxy floors compared to traditional flooring options?

Polyaspartic and epoxy floors provide several advantages over traditional flooring options. Some key benefits include:

Temperature resistance: Polyaspartic and epoxy floors can withstand a wide temperature range, from -30°F to +140°F.

Fast curing(24-48hrs): Polyaspartic(24hrs) coatings cure much faster than epoxy(48hrs), reducing downtime during installation.

UV resistance: Polyaspartic and epoxy floors are UV-resistant, meaning they do not yellow, fade, or peel when exposed to sunlight.

Stain resistance: The protective layer of these floors resists stains and is easy to clean.

Durability: Polyaspartic and epoxy floors are known for their toughness and durability.

Flexibility: While drying hard, these coatings still maintain some flexibility.

Chemical resistance: They exhibit resistance to various chemicals, making them suitable for industrial and commercial settings.

2. How long does it take to install Polyaspartic or Epoxy floors?

The installation time for polyaspartic or epoxy floors can vary depending on several factors, such as the size of the area, the condition of the substrate, and the complexity of the project. However, one of the advantages of polyaspartic and epoxy coatings is their fast curing time, which is five times faster than epoxy. For smaller projects with a quick turnaround, such as garage floors and countertops, polyaspartic coatings are especially suitable.

3. Can Polyaspartic or epoxy floors be installed over existing concrete or other types of flooring?

Polyaspartic and epoxy floors can be installed over existing concrete surfaces. However, proper surface preparation is crucial to ensure adhesion. The concrete surface should be cleaned, free of contaminants, and slightly porous to allow the coatings to adhere properly.

4. Can Polyaspartic or epoxy floors be used in both residential and commercial settings?

Yes, polyaspartic and epoxy floors are versatile and can be used in both residential and commercial settings. They are commonly applied in garages, basements, warehouses, retail stores, industrial facilities, and more.

5. Are Polyaspartic or epoxy floors suitable for outdoor applications?

Polyaspartic and epoxy floors are primarily designed for interior applications. While they can be used in some outdoor areas, they may be less suitable for prolonged exposure to direct sunlight, as UV rays can cause degradation over time.